VIPA International

The Vacuum Insulation Panel Association (VIPA International) is a global trade association representing the interests of manufacturers of Vacuum Insulation Panels (VIPs), as well as the supply chain.

How to become a member

The Vacuum Insulation Panel Association (VIPA International) is a global trade association representing the interests of manufacturers of Vacuum Insulation Panels (VIPs), as well as the supply chain.

How to become a memberVIPA International is the global voice of the VIP industry, promoting quality and raising awareness about the potential of VIPs to save space and energy costs, to increase energy efficiency and to reduce carbon dioxide emissions in a wide range of applications and industries.

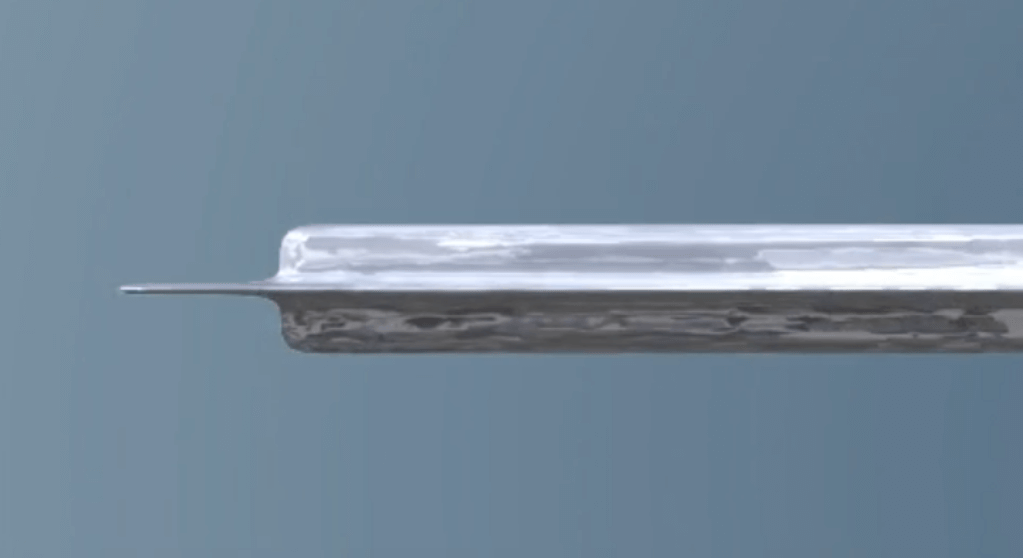

Vacuum Insulation Panels are 5 to 10 times better than other insulation materials as they have:

Between 0.002 and 0.008 w/(m*K) after production.

Applications of VIPs are very numerous: they can be used to insulate buildings (floors, roofs, facades and walls), home appliances (refrigerators, freezers and water boilers), temperature-controlled packaging solutions for medical and pharmaceutical industries or vending machines and cold store units. VIPs are also used in certain automotive applications, such as in trains, ships and airplanes.

Browse all the latest news from VIPA International

Browse all VIPA International members