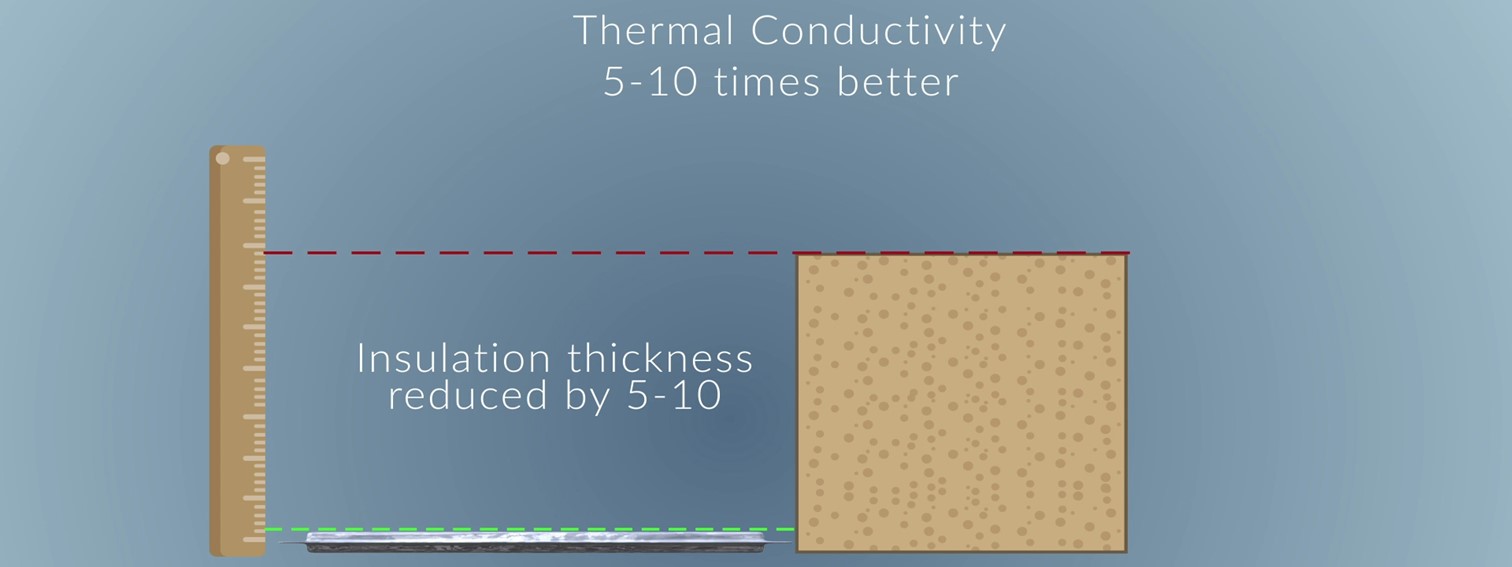

Vacuum Insulation Panels (VIPs) are a high performing insulation technology used to increase energy efficiency in a number of applications. VIPs have an extremely low thermal conductivity and low insulation thickness, which makes them valuable assets in several applications.

Thanks to the advances in materials science, now Vacuum Insulation Panels Products are broadly applied in many industries where they were not used in the past. Appliances are still one of the most common uses for VIPs. They are used in freezers and fridges, but also in water boilers and warm water storage tanks. VIPs offer substantial thermal insulation without taking up much space. This means that appliance producers can increase storage capacity without altering the exterior dimensions of the appliance.

Applications in buildings (both new construction as well as retrofits) have been growing steadily in recent years thanks to tighter building regulations at energy efficiency level. VIPs are used to insulate floors, facades (both exterior and interior), flat roofs, terraces, walls, attic hatches, stairs, etc. The use of VIPs in building applications is of particularly high value in places where space is lacking given their reduced thickness.

Other common VIP applications include:

- Refrigerated trucks and transportation systems;

- Packaging for medical and pharmaceutical industries to keep the temperature under control;

- Vending machines;

- Cold storage units;

- Fridges, freezers and wine coolers.

Vacuum Insulation Panels answer to the demands of cold-chain transport because they allow longer storage time and safer transportation conditions. A great example of this is the transportation of COVID-19 vaccines around the world, which required stable temperatures ranging from 2-8°C to as low as -20°C and even -70°C. Thanks to its low thermal conductivity, the use of VIP technology brings a great level of thermal protection for controlled refrigerated storage of high-value commodities. Furthermore, it also enables the maximum possible available internal volume within any size of the box.

Other less known VIP applications include automotive and vehicles, trains, ships and aeroplanes.

Where are Vacuum Insulation Panels used?

Discover many examples of VIP applications: