While transport applications have much in common with appliances, it is worthwhile to consider VIPs used in transport applications separately. At every step of the cold chain, there is a requirement for a temperature-controlled environment: from harvesting and food processing to transport final distribution.

For transportation, energy efficiency is an issue as well as space savings, cost and, most of all, a tightly controlled, completely reliable, unbroken cold chain. The best example of this technology is the transport of human organs for transplant surgery and the transport of certain pharmaceuticals at tightly controlled temperatures.

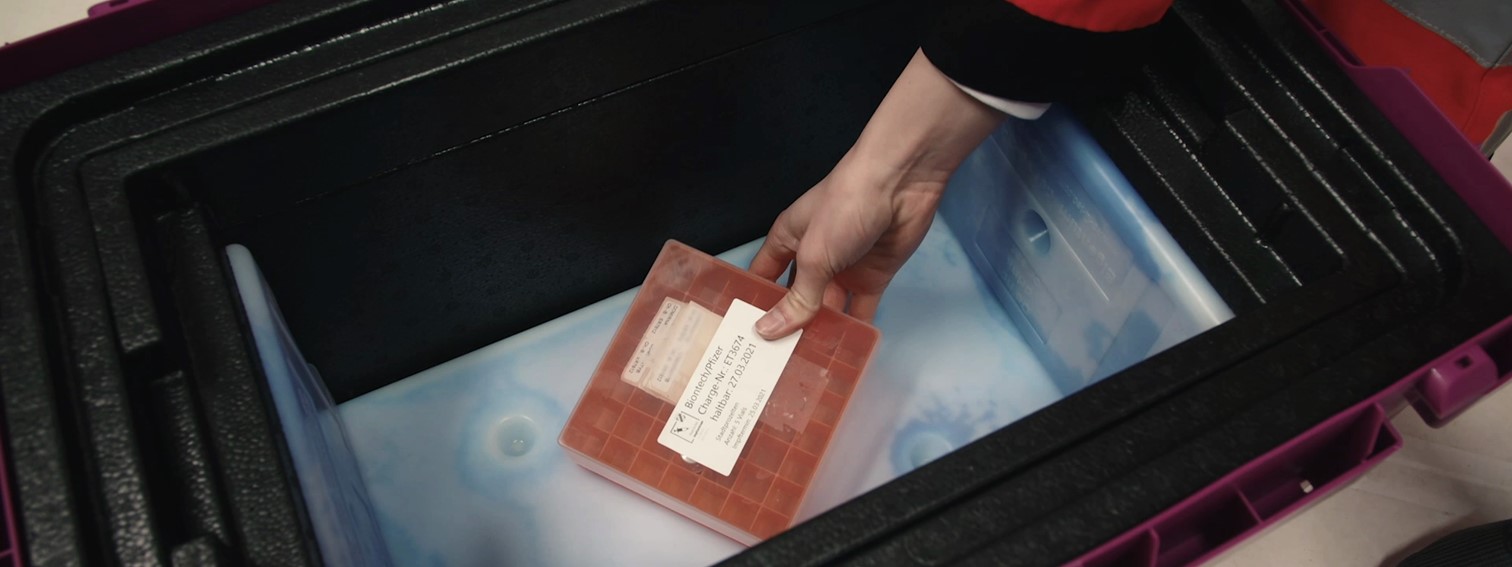

This includes COVID-19 vaccines, which require stable temperatures, ranging from 2-8°C to as low as -20°C and even -70°C.

Yet this category also includes more common applications. For example, walk-in freezers, grocery-store cold display cases, refrigerated shipping containers (reefers) and cold vending machines can all benefit from the use of VIPs. In every case, reliability and space savings are the most important benefits.

Many of the same features and properties critical to the use of VIPs in appliances are also essential to the successful application of VIPs in cold-shipping boxes and refrigerated transport. In fact, they preserve temperature-sensitive products over a range of extreme ambient conditions. VIPs deliver an ecologically friendly container solution since they are reusable, recyclable and non-toxic. They have a lower landfill footprint than standard, bulky, non-degradable insulation. The use of VIPs for higher fuel-efficient transportation also contributes to an overall improved ecological footprint.

(Source: Photo provided by Vaku-Isotherm)

Read more about how VIPs are used to transport COVID-19 vaccines