Vacuum insulation panels provide thermal protection for COVID-19 vaccine shipments

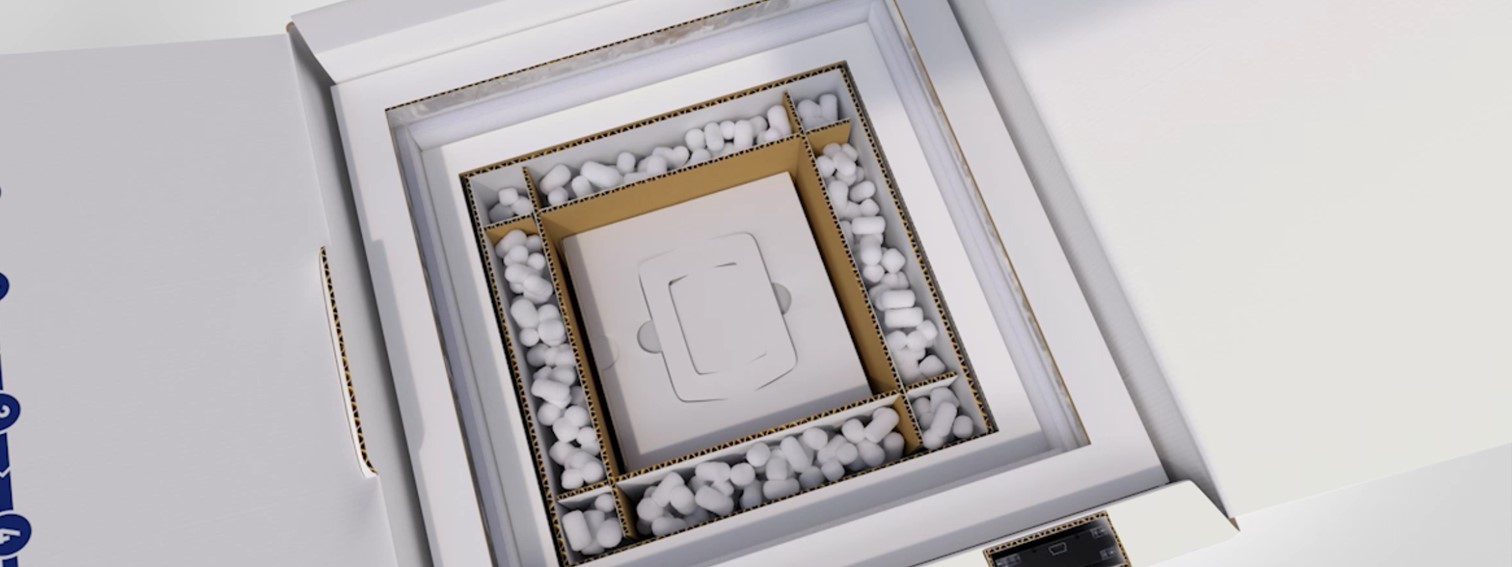

A new case study from VIPA International, the representative association of the global vacuum insulation panel industry, explains why vacuum insulation panels (VIPs) were one of the key technologies chosen to transport shipments of the Pfizer-BioNTech COVID-19 Vaccine (BNT162b2) from BioNTech facilities.

VIPs’ high insulation performance allows for steady temperatures for up to 10 days without power and gives enhanced resistance in extreme climatic conditions, which is especially effective for the ‘soft last mile’ to the vaccination centres and doctors’ offices. Their low insulation thickness also allows for thinner container and packaging walls, meaning that more vaccines can be shipped per journey.

In this case study, the tailor-made double-wall VIP insulated shipper maintains -70°C for a minimum of 240 hours providing the necessary temperature protection for vaccine shipments from BioNTech’s facilities in Germany. The cooling chain is kept with the addition of dry ice as needed but no further equipment is necessary.

“The extremely low thermal conductivity combined with the low thickness make vacuum insulation panels a key technology for shipping COVID-19 vaccines around the world. We are pleased to be contributing to the fight against the pandemic by ensuring vaccines as well as other life-saving products arrive at their destination in perfect conditions,” said VIPA Intl Board member Tom Heckard from CSafe Global.

To learn more about the transport of COVID vaccines with VIPs check our video and dedicated page.