All you need to know about vacuum insulation panels and the transport of COVID-19 vaccines across the world

The mass COVID-19 vaccine rollout presents an unprecedented logistical challenge as billions of vaccines need to be shipped around the world at stable temperatures, ranging from 2-8°C to as low as -20°C and even -70°C.

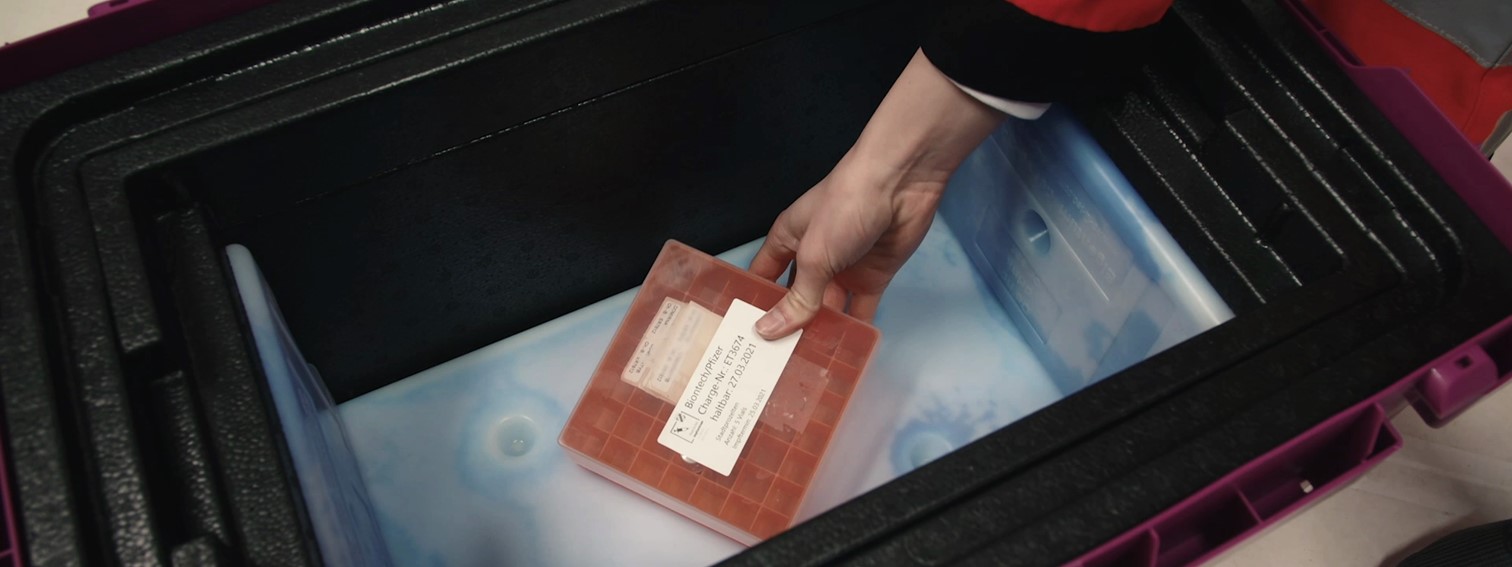

Climate-controlled transportation requires strict regulation of a set temperature. The temperature must be consistent and reliably maintain the set values for long durations throughout the whole transport process, where external temperatures can fluctuate wildly and unpredictably.

Vacuum Insulation Panels (VIPs) have been prevalent in the cold chain, climate-controlled packaging markets for many years and have unique characteristics that make them ideal for temperature controlled transportation, such as:

- Extremely low thermal conductivity (0.002 and 0.008 W/(m·K) after production)

- Long-term thermal performance

- Increased energy efficiency

- Low insulation thickness (10 mm to 25 mm)

VIPA International members have been actively collaborating with refrigeration equipment manufacturers to ensure the transportation boxes and containers carrying COVID-19 vaccines are meeting the highest standards of quality, enabling a fast and reliable rollout of the vaccines around the world.

Sebastian Baars, CEO of Vaku Isotherm and President of VIPA International said: “In the past months, the demand for our technology has increased exponentially. We are obviously pleased to be part of the solution to this pandemic and hope the increased attention to the use of VIPs in temperature controlled logistics will also impact positively on the other applications of our product.”

What are vacuum insulation panels (VIPs)?

VIPs are ultra-thin, high-performing insulation materials that consist of a rigid, highly porous core material encased in a thin, gas-tight outer envelope, which is evacuated and sealed to prevent outside gases and humidity from entering the panel. The combination of porous material and the vacuum results in an extremely high thermal resistance. VIPs have many applications, most commonly in appliances, temperature controlled transportation and buildings.

More information is available here: https://vipa-international.orghow-vips-are-used-to-transport-covid-19-vaccines/

What are VIPs made of?

The most common core materials used for VIPs are fumed silica and glass fibres. For the envelope material, most manufacturers use aluminium-metallised high barrier plastic laminates, aluminium composite films and stainless-steel films or sheets.

Why are VIPs ideal for transporting COVID-19 vaccines around the world?

VIPs have a thermal conductivity between 0.002 and 0.008 W/(m·K) after production, which is 5 to 10 times better than other insulation materials. This results in high insulation values, which provide increased durational performance, allowing stable temperatures for up to 10 days without power, almost 3x longer than alternate insulation technologies and so an enhanced resistance in extreme climatic conditions.

Furthermore, VIPs have a low insulation thickness (10 mm to 25 mm). This allows for thinner container and packaging walls, maximising the usable space per shipment. This in turn means that more vaccines can be shipped with fewer journeys, which also helps to reduce the overall carbon footprint.

Where are vacuum insulation panels produced?

VIPA International members from all around the world manufacture VIPs. See a full list here: https://vipa-international.orgabout-vipa-international/

How sustainable is this technology?

VIPs have a very stable, long-term thermal performance when installed correctly and protected from damage and penetration. The product reaches the end of its service life when the gas pressure rises above 50 to 100 mbar. For temperature controlled logistic applications they can be reused as well as recycled at the end of life, and have a lower landfill footprint than standard insulation, making them an environmentally sustainable solution.

Furthermore, since VIPs are much thinner than standard insulation, there is more usable space per shipment, making the transportation much more fuel-efficient and contributing to a lower ecological footprint.

In which other application can vacuum insulation panels be used?

The three main applications are household appliances, temperature-controlled transportation and buildings, but VIPs can also be used in automotive and vehicle applications, including trains, ships and aeroplanes.

The appliance sector accounts for the vast majority of the market. They have been used in refrigerators, freezers and water boilers for decades. Thanks to their outstanding thermal performance, the use of VIPs in household appliances allows them to qualify for the highest energy class in the European Union and in the USA (energy star system). Watch our animated video about VIPs used in appliances: https://youtu.be/otZahlZtDMQ

In the building construction segment, VIPs enable low-energy buildings and are used for renovations, especially in areas where space is at premium. Common applications include roofs, floors, façades, balconies, terraces and both internal and external wall insulation. Watch our animated video about VIPs used in buildings: https://youtu.be/SrkgfxL0sNA

In the transportation segment, VIPs are used in the healthcare and pharma, logistics and food industries. Examples include walk-in freezers, containers and boxes, grocery-store cold display cases, refrigerated shipping containers (reefers) and cold vending machines, to mention just a few.