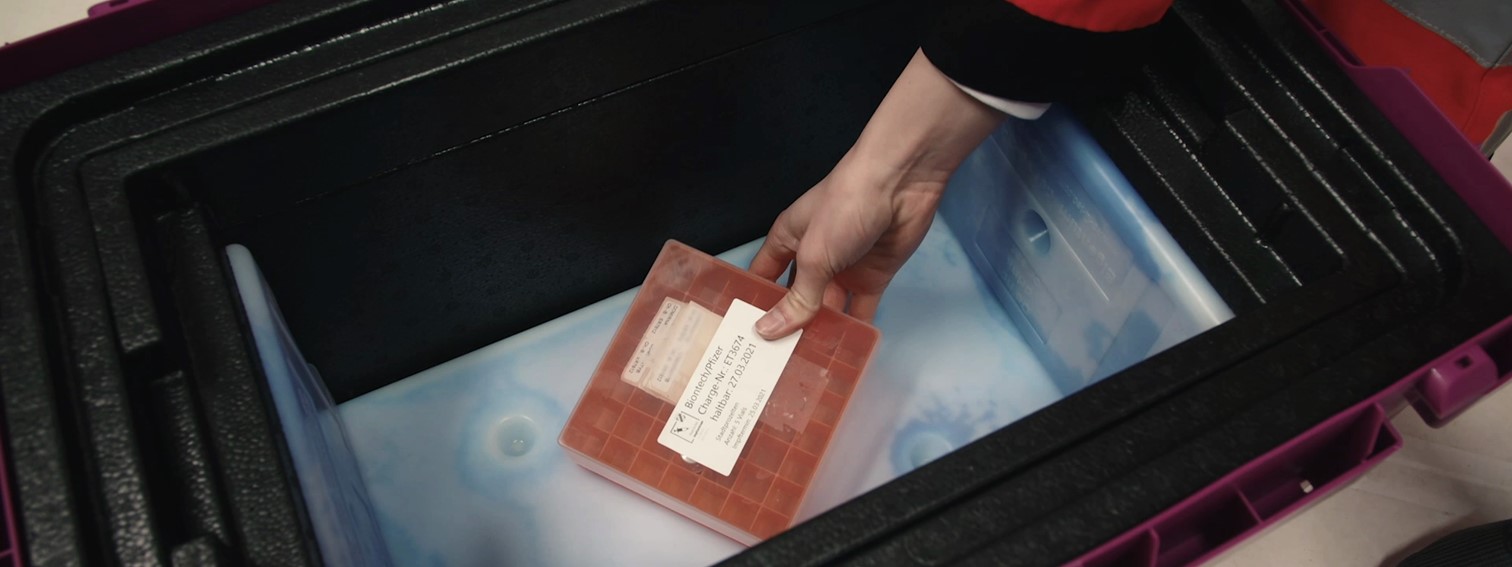

Vacuum Insulation Panels enable COVID-19 vaccines to be shipped around the world

A new video from VIPA Int’l, the representative association of the global vacuum insulation panel (VIP) industry, demonstrates how VIPs help solve the unprecedented logistical challenge of shipping billions of COVID-19 vaccines around the world at very low temperatures (-20°C to -70°C).

VIPs’ high insulation values enable stable temperatures for up to 10 days without power and give enhanced resistance in extreme climatic conditions, which is especially effective for the ‘soft last mile’ to the vaccination centres and doctors’ offices. Their low insulation thickness also allows for thinner container and packaging walls, meaning that more vaccines can be shipped per journey.

Sebastian Baars, President of VIPA Int’l, said:

“VIPs have unique characteristics that make them ideal for shipping COVID-19 vaccines around the world, which is why they have been used for many years to transport other life-saving products, such as organs for transplant and blood for transfusions.

“Our industry is very proud to be a part of the solution to this pandemic and VIPA Int’l members have been working with refrigeration equipment manufacturers to ensure that boxes and containers for COVID-19 vaccines are meeting the highest quality standards.”

VIPs have been prevalent in temperature-controlled packaging for many years, but they are also commonly used in appliances and buildings, among other applications. As well as being highly energy efficient and saving space, they are also reusable, recyclable and non-toxic, making them an environmentally-friendly option.

Watch the video below.

Read more about how VIPs are used to transport COVID vaccines here.